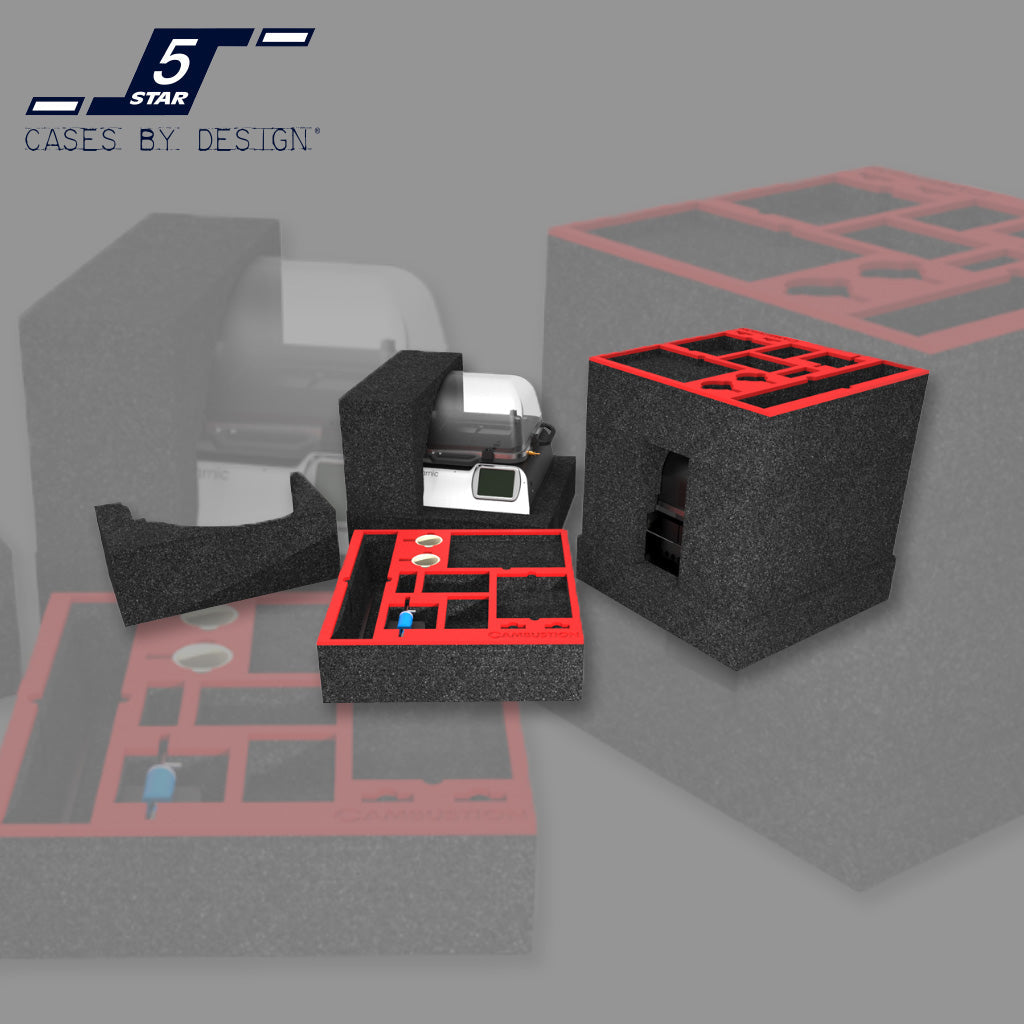

Collection: Foam Inserts

Foam inserts for flight cases from Europe's leading case manufacturer is the first choice for equipment protection.

5 Star Cases has been involved in foam inserts for flight cases for many decades and in that time have gained much experience in the design and manufacture of foam inserts for cases. We have at our disposal a wide range of foam fabrication equipment, and continued investment means that this department is able to cope with most foam insert fabrication requirements. At the Broadend Road site, the company has a vast array of foam fabrication facilities at its disposal. Not only this, but many of the staff employed in the department have been with us for many years. We keep a vast stock of raw materials which ensures prompt deliveries.

These materials include…

- – Polyethylene Sheet

- – Polyurethane HLB Blocks

- – Profiled Polyurethane

- – Brushed Nylon Facing

- – Coloured Suedette Facings

- – PVC Coating

- – Anti-Static Jiffycell®

Our stocks of foam sheet, block and facing materials are usually sufficient to meet most requirements. But our suppliers also keep many other foam types including coloured polyethylene, neoprene, natural rubber and expanded EPDM. These can be ordered specially to individual requirements. Please contact our sales team for further details on our foam types.

The materials mentioned above can be used in combination with others. For instance, polyurethane (HLB) is often bonded to polyethylene to give additional protection. While different grades of polyethylene are bonded to each other, again where varying protection is required. Technical Data sheets are available for all our foam and associated media which are available upon request.

Foam inserts for flight cases & IP67 cases can be fabricated in many ways. One of which is via CNC routing, using one of our Multicam machining centres. These types of inserts are best suited for single and low production runs. Customers can supply the overall layout of the flight case insert as a DXF file, ready for us to toolpath to the desired depths or send us the actual items and we’ll do the rest. We can also scan an image of the item as long as it’s accurately drawn.

It's also possible to CNC route contrasting coloured polyethylene foam, meaning the lower layer of the foam can be a different colour to the top layer. This makes the foam really stand out it and it makes it much easier to identify the cutouts. A handy feature for ensuring equipment is where it should be!

Traditional die cut foam inserts are also still popular. A press tool is a series of custom shaped blades held in a plywood board which are manufactured by laser cutting and bending machines. Once made, these press tools are numbered and stored at our premises. Pressed foams are more cost effective on multiple and repeat orders.

For further details on Foam Inserts for flight cases and associated products, contact our sales team.